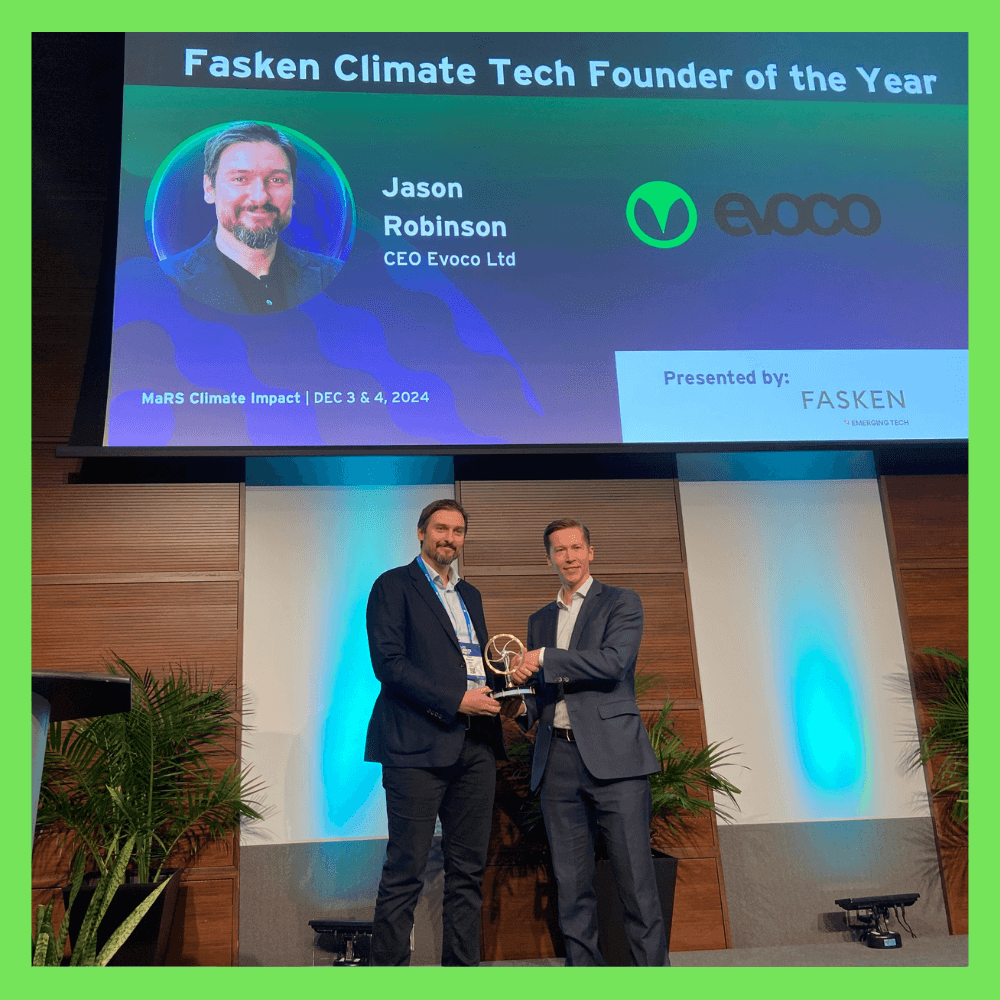

Toronto, Canada, Sept. 29, 2023 – Evoco, a global innovation company founded to defossilize the material value chain, announced today that its Co-Founder and CEO Jason Robinson has been recognized as a 2024 Clean50 Honouree

“Canada’s Clean50 Awards are announced annually by Delta Management Group and the Clean50 organization to recognize those 50 individuals who have done the most to advance the cause of sustainability and clean capitalism in Canada over the past 2 years,” said Gavin Pitchford, Delta Management Group CEO.

“This national environmental recognition is a testament to our team’s trailblazing efforts and dedication in creating and scaling innovative material solutions with measurable and verifiable impact” said Jason Robinson. “And as a strong proponent of cross-sectorial collaboration, I value this unique opportunity to engage with other sustainability leaders from all sectors of the Canadian economy.”

As a disruptive pioneer in the industry with 20 years of experience in renewable and cleantech technologies, Jason is focused on creating better-performing, responsible, and ecological products. His expertise in engineering and science has prepared him to charter this new territory and challenge the status quo every step of the way.

Evoco is committed to authentic sustainability, helping numerous consumer brands de-fossilize their supply chains by providing them with plant-based material solutions, such as FATES™, its eco-foam. Now commercialized, FATES cuts carbon emissions by up to 70% and minimizes the product’s end-of-life impact through its advanced detoxifying properties.

Starting in footwear first with global brand partners such as shoe giant VANS, the switch to FATES™ resulted in a reduction of over 1.4 KT CO2e greenhouse gas emissions so far.

At a time when transparency means everything, peeling back on what it means to be green is a driving force for Evoco’s Co-Founder and CEO, Jason Robinson.

To combat greenwashing, Evoco’s 70 to 80% plant-based materials are third-party certified by USDA and GreenCircle, as well as Vegan certified, as there are no animal-derived products.

Moving into 2024, Evoco will continue to innovate through plant-based materials that reduce carbon emissions without compromising performance, revolutionizing the materials used in the products we walk in, sleep in, and drive in.

For more information, contact:

Gerald Alvoet

VP of Marketing

galvoet@evocoltd.com

+1-647-299-0553

About Evoco Ltd

Evoco Ltd is a global innovation company founded to close the loop on unsustainable goods, for good. Harnessing the power of nature, Evoco leverages its plant-based chemistry platform to create scalable novel materials to help its brand partners develop the next generation of high-performing, low carbon products, with minimal impact at end of life. Starting with footwear, Evoco’s solutions have been adopted by a variety of global brands, such as Vans, Kodiak, Bared, Timberland and Keen.

Through an expansive innovation roadmap led through our R&D center in Toronto, Canada, Evoco is expanding its material solutions to positively impact everything we walk on, sit on, drive in and sleep on.

About Delta Management Group / Canada’s Clean50

Leading ESG, sustainability and clean tech search firm Delta Management Group founded, and remains the steward of the Canada’s Clean50 awards, created in 2011 to annually identify, recognize and connect 50 sustainability leaders from every sector of Canadian endeavor, in order to facilitate understanding, collaboration and innovation in the fight to keep climate change impacts below 1.5 degrees C. Ancillary awards also recognize 20 Emerging Leaders and the 25 Top Sustainability Projects of the year, as well as bestow Lifetime Achievement designations.